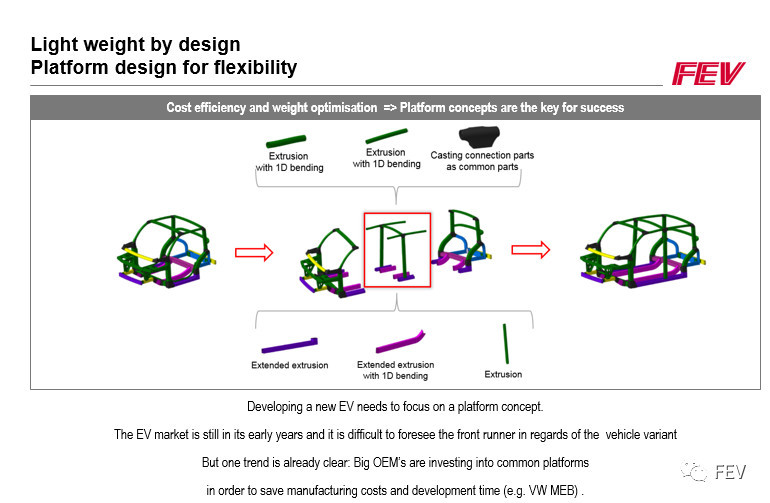

Developing a new EV needs to focus on a platform concept. The EV market is still in its early years and it is difficult to foresee the front runner in regards of the vehicle variant. But one trend is already clear: Big OEM’s are investing into common platforms, in order to save manufacturing costs and development time.

开发新的电动车需要关注于平台概念设计。电动车市场目前还处于发展的初级阶段,很难预测未来哪种车型能够更好地适应市场。但是,一个大体的趋势已经明确了:几乎所有的大型主机厂都开始投资开发自己的通用平台,这样可以更好的节省制造成本及研发时间。

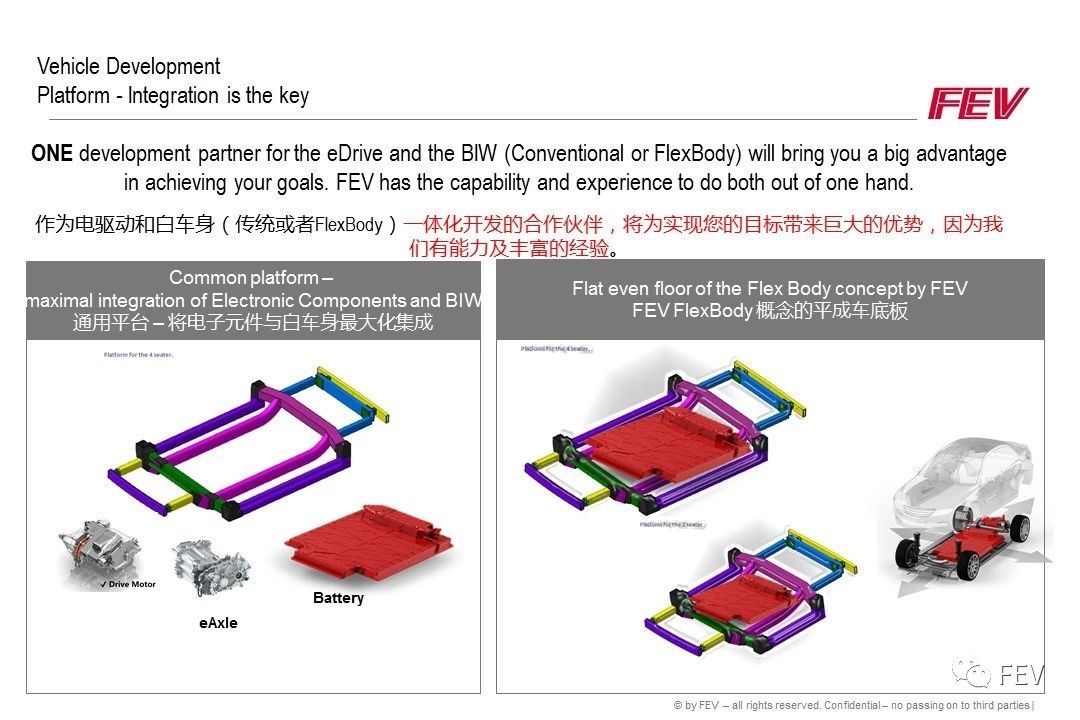

For new players and lower volume vehicles a ‘space frame’ solution could be an advantage. Low tooling investment let you test the market without spending too much money. The FEV FlexBody concept gives you also the safety for a long-term future as you need to have more than one model in the race in order to achieve a sustainable annual volume.

针对电动市场新的主机厂和目标为较低产量的电动车,框架式结构的解决方案可以提供很大优势。较低的模具投资可以允许主机厂在低投入的情况下提前测试市场反馈。FEV独特的Flexbody是一个成熟的概念,可以为主机厂提供一个安全长远的解决方案。平台式框架结构可以应用于不同车型。

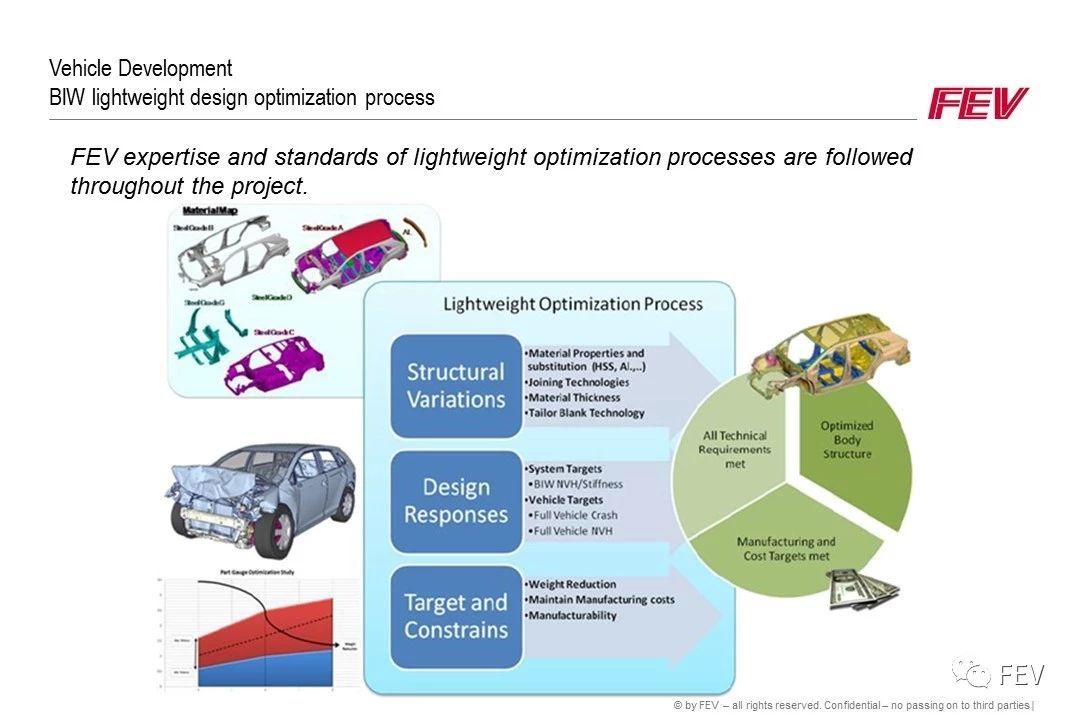

During EV development, after we define the variants and have a basic idea on the platform, lightweight design process needs to be taken into consideration. Lightweight design process includes 3 main sections:

- Structural variations, including what kind of materials/joining technologies are using and can you optimize the structure to the maximum.

- Design responses, including target setting on the whole system and the performance. Are these targets well considered? Not going over engineered?

- Target and constrains, including costs and manufacturability, how much are you willing to pay for the lightweight solutions?

电动车开发过程中,在我们定义了车型以及对平台有了基本的概念之后,轻量化设计流程需要被尽早考虑。轻量化的设计流程主要包括以下几个方面:

- 结构变形:包括材料,连接技术方面的使用,以及是否可以将结构最大化优化

- 设计反馈:包括针对整个系统及性能的目标值设定,这些目标值是否经过详细的考虑,是否设定过度?

- 目标及约束条件:包括成本及制造可行性,为了满足轻量化要求,你愿意付出多少的成本?

If you missed the opportunity to consider lightweight in the early stage, there are also chances to optimize the product base on FEV’s strong design/simulation capability.

如果您已经错失了尽早考虑轻量化的机会,基于FEV强大的设计仿真能力,您还有机会进行补救。

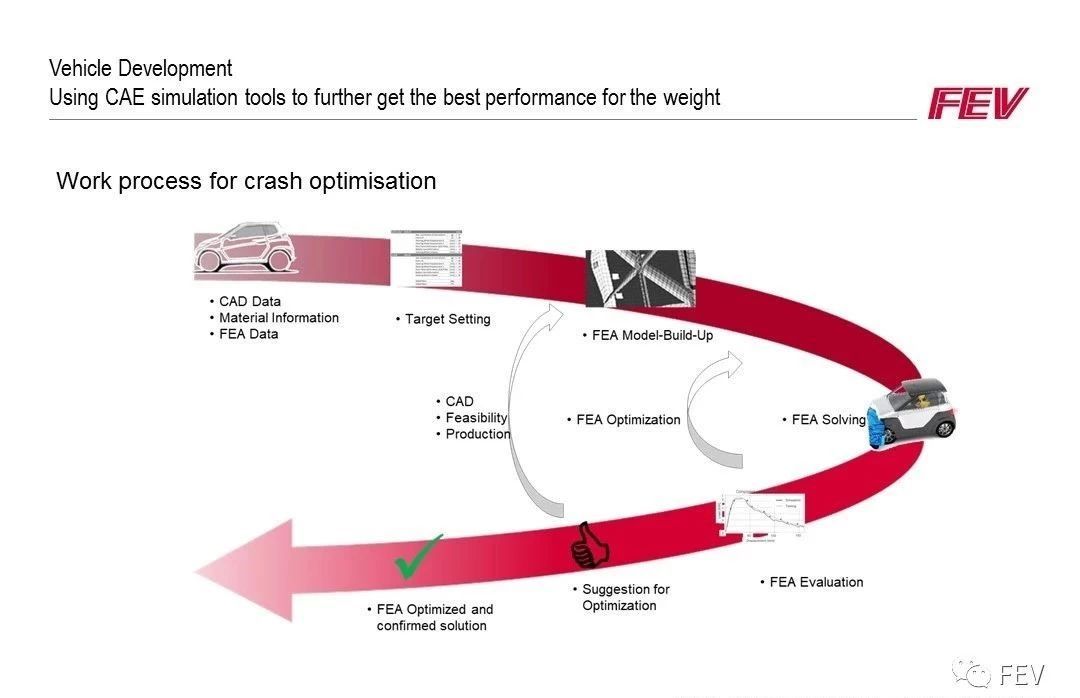

The process could be simply summarize as below: after we check on the current data and set up/review the targets, FEA model has been built up. Following procedure will be model solving and several optimization loops. We first propose and simulate the solution in CAE and then, in parallel CAD will optimize the structure base on CAE inputs. This loop will be executed until we achieve all target.

这个流程可以被简单总结如下图:在我们检查现有数据及建立或对目前的目标值进行评估之后,我们将建立有限元模型。下一步将会是模型的计算及几轮优化循环。我们刚一开始将基于CAE结果在CAE模型中进行更改及仿真,然后,基于CAE输入的CAD的优化结构设计将会平行进行。这种循环将会一直持续直到我们满足所有目标。

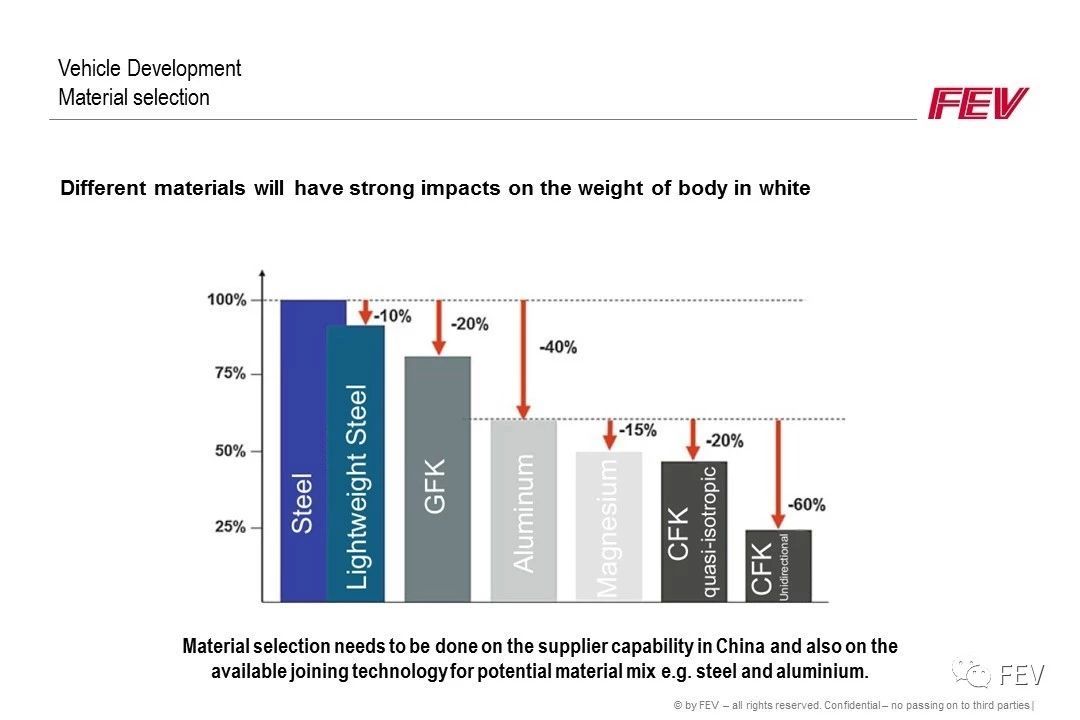

At the end of this essay, the material impact and solutions will be introduced. Below chart is a study carry out by FEV, if you introduce lightweight materials into conventional steel structure, it will, of course, save more weight by default. E.g. If you want to build up a full aluminum body in white vehicle, you can save up to 40% of the weight compare to conventional body in white.

在文章的最后,我们将讨论不同材料选择的影响及解决方案。如下图FEV研究表明,如果您将轻量化材料引入到传统的钢结构白车身中,当然,您将会节省更多的重量。例如如果您想设计一个全铝车身,与传统钢结构车身相比,您大概将会节省40%左右的重量。

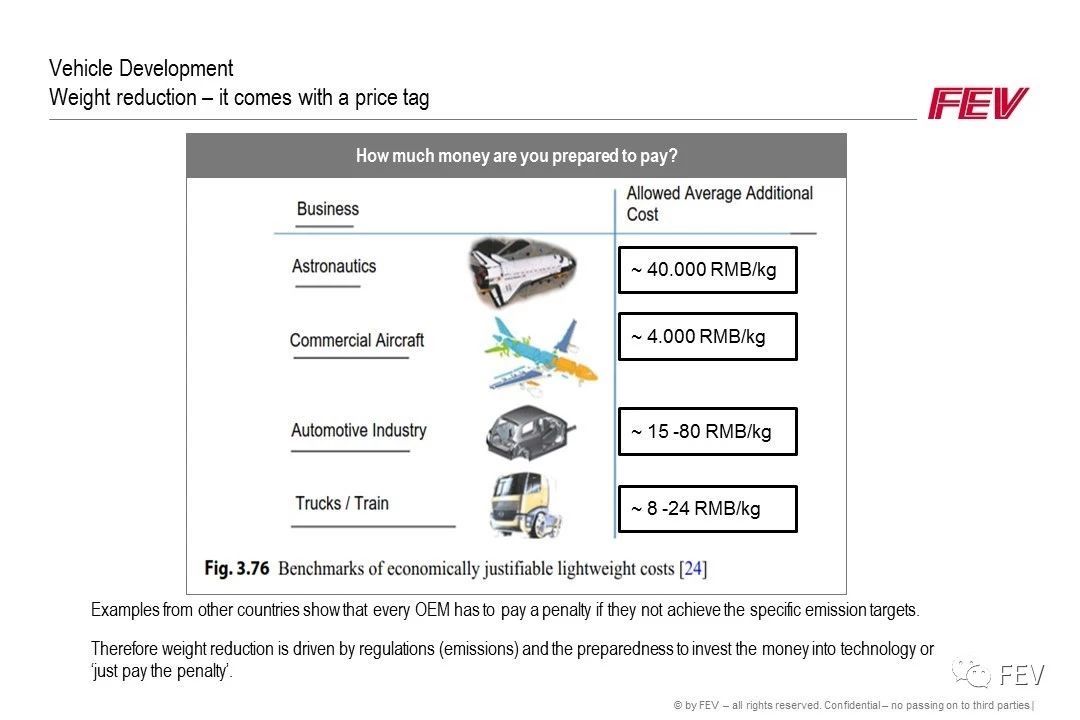

We also done a study from the commercial side. In every industry, you have to pay for the lightweight solutions. There is no solution to save both cost and weight unless we start from a relatively basic structure. In the automotive industry, it cost roughly 15~80 RMB if you try to save 1 kg in your vehicle.

我们同样针对轻量化的方面,做了商业相关的研究。在每个产业中,您必须为轻量化付出相应的代价。目前并没有一个解决方案能一起节省成本及重量,除非我们的基准是一个相对于初级的结构。在汽车产业中,每公斤的轻量化设计将花费大概15~80 人民币。

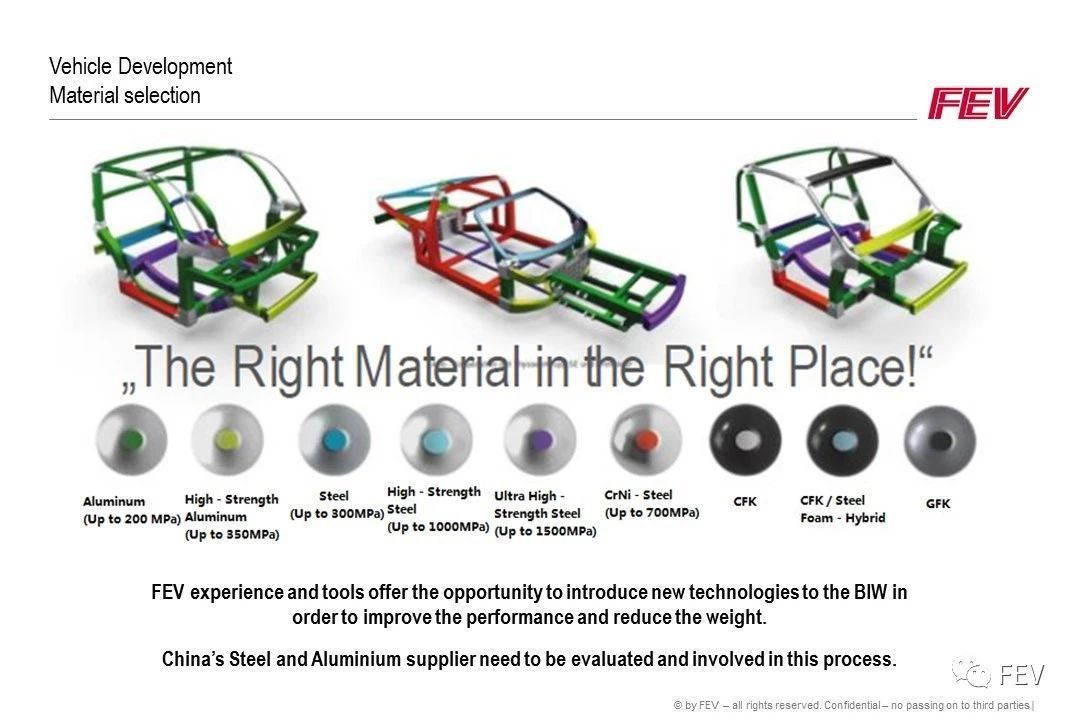

At the end, we always say “the right material in the right place.” You may have to include different materials in the body in white design, however, it doesn't make sense if you put it in the wrong area. FEV has the tools and experiences to distribute the materials if needed, or simply speaking, build an aluminum & steel body in white efficiently and get the most benefits on cost & weight.

最后,我们一直说“在正确的位置使用正确的材料”。有些时候,在白车身设计中我们需要包含不同材料设计,然而,在错误的区域使用了不恰当的材料并不能起到优化性能的目的。FEV有足够的经验及工具来正确分布材料。或者换句话来讲,更有效的开发一款钢铝混合车身并达到重量与成本的最佳平衡。

总部位于德国亚琛的FEV集团是一家国际化动力系统及整车开发服务供应商。FEV为全世界客户提供上述服务。集团拥有超过5600名技术专家,并在四大洲建立了40处研发机构同客户一道工作。FEV已在中国市场活跃25年,FEV中国在北京、上海、大连、武汉、重庆等地设立分公司和办公室,更好服务中国本土客户。

广告

广告